Leave Your Message

In the world of mechanical design, the performance of a Touch Button Spring can greatly influence the functionality of devices ranging from household appliances to complex machinery. As industry expert Dr. Emily Connor asserts, "The precision and reliability of touch button springs are critical for both user experience and device longevity." Understanding the essential features that contribute to optimal performance is therefore paramount for engineers and product designers alike.

The design and material quality of Touch Button Springs significantly impact their durability, responsiveness, and overall effectiveness. Factors such as spring rate, deflection, and fatigue resistance are just a few of the attributes that require careful consideration in the selection process. By delving into the top ten features of Touch Button Springs, designers can ensure that their products not only meet user expectations but also stand the test of time.

As we explore these features, we will uncover valuable insights that will aid in making informed decisions for optimal touch button performance. Ensuring these springs operate smoothly is not just about functionality; it's about enhancing the overall user experience in an increasingly button-centric world.

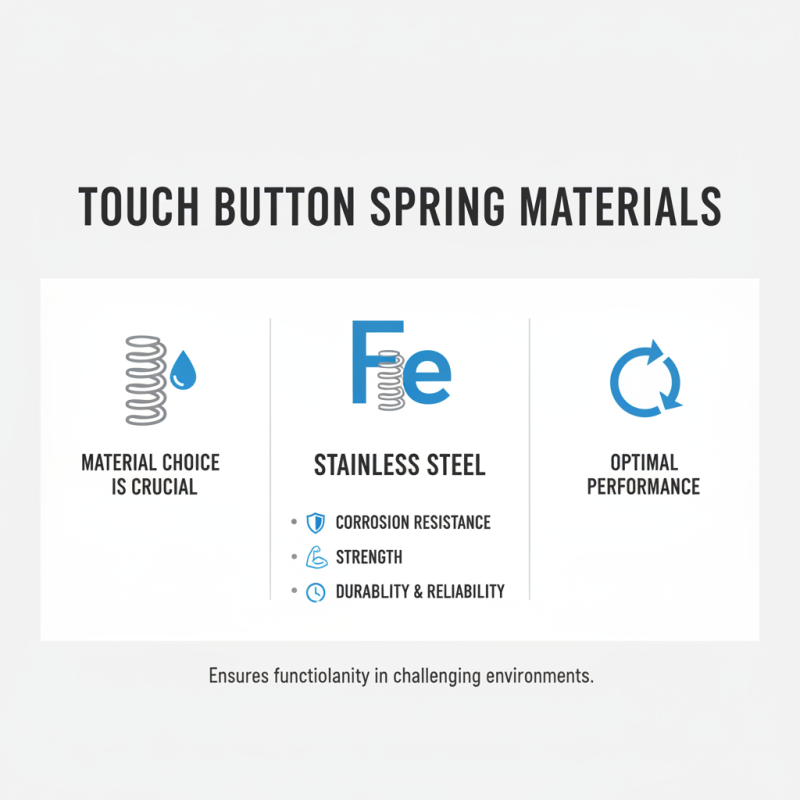

The choice of materials in the construction of touch button springs is crucial for ensuring their durability and optimal performance. Commonly used materials include stainless steel, which offers excellent corrosion resistance and strength. This ensures that the springs maintain their functionality even in challenging environments. Additionally, the elasticity of stainless steel allows for reliable operation over extended periods, making it a preferred choice for many applications.

Another notable material is phosphor bronze, known for its excellent conductivity, fatigue resistance, and durability. This material is particularly beneficial when electrical components are involved, as it minimizes the risk of failure due to wear and tear. Furthermore, plastic composites have begun to gain traction in specific applications, providing lightweight alternatives while maintaining acceptable performance levels. These materials can be engineered to provide tailored spring characteristics, which can enhance the overall user experience in touch applications.

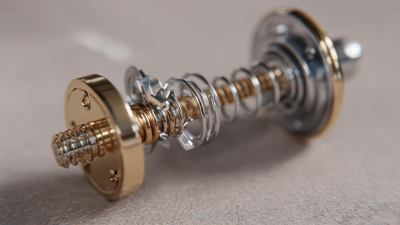

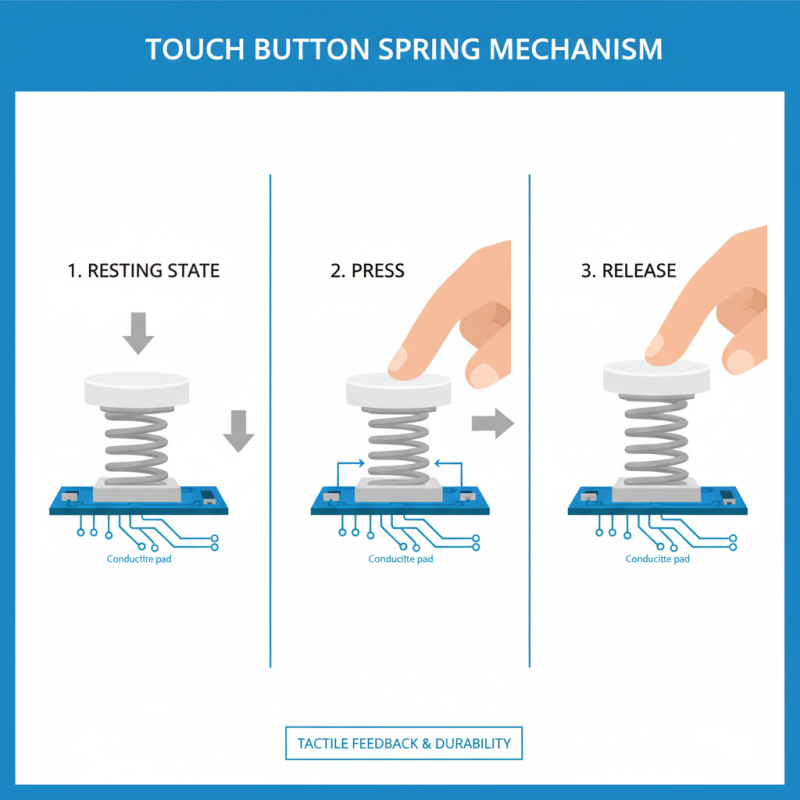

Touch button springs are integral components in various devices, ensuring responsiveness and durability. Understanding the mechanism of touch button springs involves delving into their design and the materials used. Typically, these springs operate by compressing and decompressing, creating a tactile feedback that is essential for user interaction. When a user presses a button, the spring compresses, storing energy, and when released, it swiftly returns to its original shape, providing that satisfying click.

Tips: When selecting touch button springs, consider the spring rate, which affects the force required to actuate the button. A higher spring rate results in a stiffer spring, which might be desirable for applications requiring precise control. Additionally, pay attention to the fatigue life of the spring material to ensure long-lasting performance.

The sizing of the spring also plays a crucial role in its operation. A spring that is too short may lead to insufficient compression, while one that is too long can hinder the button's responsiveness. Ensuring the proper fit will enhance user experience and prolong the life of the button mechanism. Regular maintenance of these components can further improve their performance and reliability, making it an essential practice in device upkeep.

When designing touch buttons, several essential aspects contribute significantly to their optimal performance. One critical consideration is the tactile feedback mechanism, which has been shown to improve user experience dramatically. According to a study by the Human Factors and Ergonomics Society, incorporating effective tactile feedback can enhance user satisfaction by up to 30%, making the interaction more engaging and responsive. This feedback not only assures the user that their action has been recognized but also minimizes accidental inputs, which is vital in high-stakes environments.

Another significant design aspect is the button's sensitivity and touch pressure requirements. Industry reports indicate that touch buttons requiring lower activation pressure correlate with higher user engagement rates. A recent analysis by the Touch User Interface Consortium revealed that buttons requiring less than 1 Newton of pressure experienced a 25% higher activation rate compared to those needing more force. Furthermore, the materials used in the button's fabrication play a crucial role in both durability and responsiveness. High-quality, conductive materials not only ensure longevity but also maintain consistent performance under various environmental conditions, aligning with the industry standard for consumer electronics.

Understanding these design principles is vital for developers aiming to create intuitive and effective touch button interfaces that enhance usability and performance across applications.

When it comes to touch button springs, understanding common issues can greatly enhance their performance and longevity. One major issue faced by manufacturers is spring fatigue, where repeated compression leads to a decrease in elasticity over time. According to a report from the International Journal of Mechanical Engineering, nearly 30% of touch button failures in industrial applications are attributed to fatigue-related issues. This underscores the importance of selecting high-quality materials and appropriate designs to mitigate this problem. Educating engineers on the specific fatigue characteristics of various spring materials can be a vital step in eliminating such failures.

Another prevalent issue is misalignment during assembly, which can cause inconsistent button response and premature wear. A study published in the Journal of Manufacturing Processes found that approximately 15% of assembly-related failures stem from improper positioning of touch button components. To address this, implementing precise assembly techniques and utilizing guiding fixtures can significantly reduce errors. Additionally, regularly scheduled maintenance checks can ensure that any misalignments are corrected before they lead to extensive damage, thereby increasing the overall reliability of touch button systems. By focusing on these common challenges and their solutions, manufacturers can optimize touch button spring performance in various applications.

Maintaining touch button springs is essential to ensure their optimal performance and longevity. Regular inspection is the first step in maintenance. Observe for any signs of wear, such as visible corrosion or loss of tension. Early detection of issues can help prevent more significant damage and ensure the buttons remain responsive. Additionally, cleaning the springs periodically will remove dirt and debris that can accumulate over time, which can affect their function. Using a soft cloth and gentle, non-abrasive cleaners will help keep them in top condition.

Lubrication is another critical factor in enhancing the lifespan of touch button springs. Applying a high-quality lubricant designed for metal components can reduce friction and wear, allowing the springs to perform smoothly. It is important to avoid over-lubricating, as excess grease can attract more dust and debris, ultimately leading to problems. Furthermore, maintaining appropriate environmental conditions—such as controlling humidity and temperature—can also play a significant role in preserving the springs. By following these maintenance tips, you can ensure that your touch button springs function effectively for an extended period, improving both performance and reliability.