Leave Your Message

The efficient use of SMD Electronic Component Carrier Tape is critical in the electronics manufacturing industry, where precision and speed are paramount. According to a report by the IPC (Institute for Interconnecting and Packaging Electronic Circuits), improper handling of carrier tape can lead to significant production delays and increases in assembly line costs. Despite the advancements in automated processes, studies indicate that upwards of 30% of electronic manufacturing defects can be attributed to issues with component handling and presentation. This underscores the need for optimized strategies in the application of SMD Electronic Component Carrier Tape, which not only enhances the reliability of component placement but also mitigates risks associated with damage during transfer.

In this blog, we will explore ten proven strategies that can streamline the use of carrier tape and improve overall operational efficiency, ensuring that manufacturers can meet the growing demands of the market while maintaining high-quality production standards.

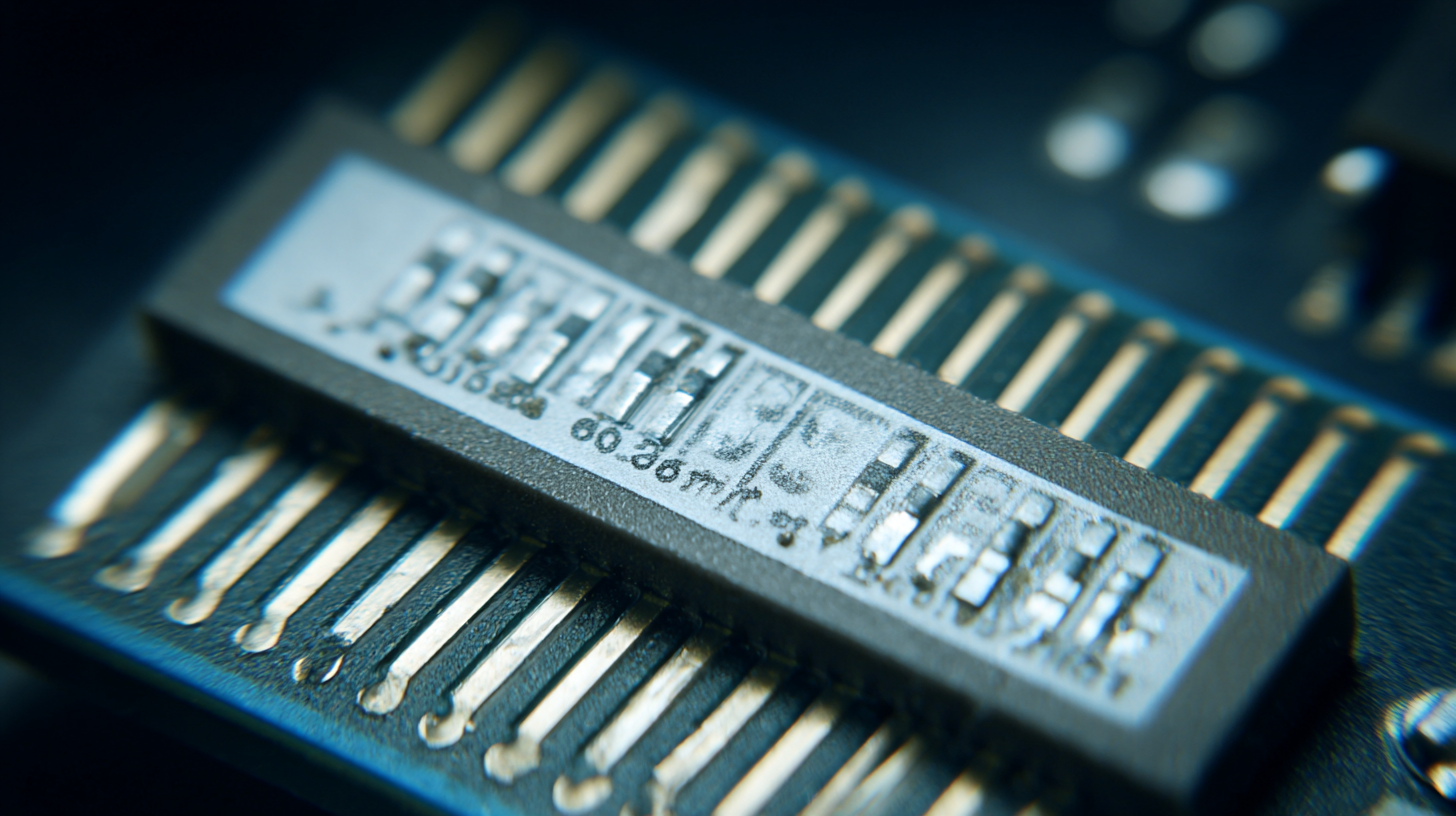

When it comes to selecting the right carrier tape specifications in SMD assembly, several crucial factors come into play. Firstly, understanding the dimensions and types of electronic components to be housed is essential. Carrier tapes are designed to accommodate various sizes and shapes of SMD components, so careful measurement of component height, width, and pitch is necessary to ensure proper fit and protection during transport and assembly. Additionally, selecting the right material—be it plastic, conductive, or anti-static—is important for preserving the integrity of sensitive components and preventing any potential damage.

Another vital aspect is the selection of the sprocket holes and the spacing between them. This affects the feeding mechanism of automated pick-and-place machines, which rely on accurate alignment for effective operation. Ensuring that the specifications match the equipment being used can significantly reduce setup time and minimize errors during the assembly process. Furthermore, considering environmental factors such as humidity and temperature can influence the performance of carrier tapes, making it critical to select tapes that withstand the specific conditions they will encounter. By paying attention to these details, manufacturers can optimize their SMD assembly processes and enhance overall efficiency.

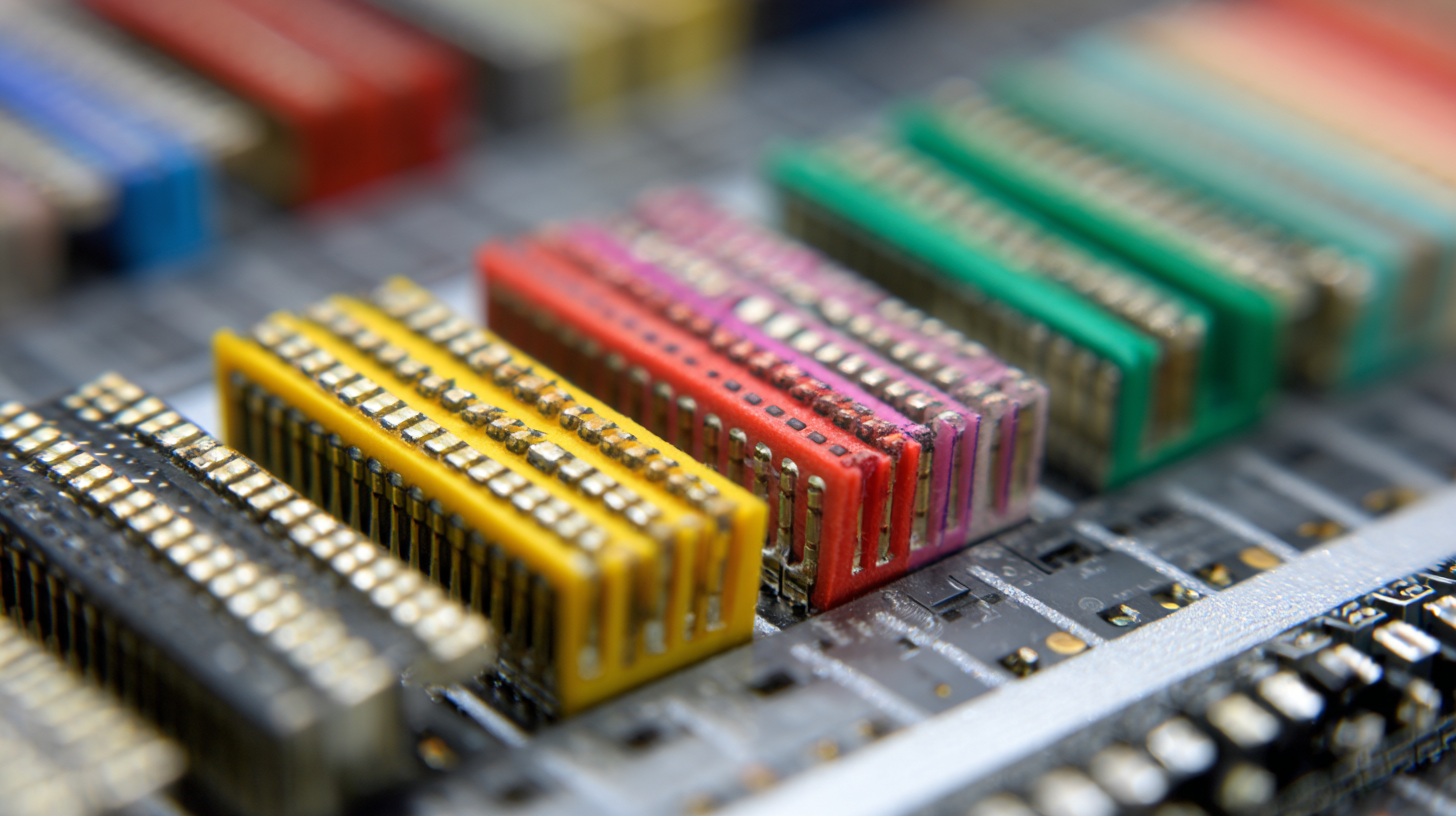

The use of carrier tape for SMD electronic components is pivotal in enhancing storage efficiency, particularly when it comes to understanding the specific dimensions and reel sizes. Properly designed carrier tapes can notably reduce waste and improve inventory management. According to industry reports, standard carrier tapes typically vary in width from 8 mm to 44 mm, accommodating different component sizes while optimizing both storage and retrieval processes. The choice of reel size is equally important; common reel diameters such as 7-inch and 13-inch significantly influence the shipping costs and storage capabilities of your components.

As the market for electronic components continues to grow, understanding carrier tape dimensions becomes essential for manufacturers aiming to streamline their operations. A recent analysis revealed that implementing optimized carrier tape solutions could enhance packing density by up to 25%, thereby minimizing the footprint required for component storage. Moreover, the integration of advanced tape materials has improved durability and flexibility, allowing for better performance during automated handling systems. This ultimately leads to more efficient production timelines and reduced operational costs, making it crucial for companies to leverage these insights in their strategy.

Proper handling and loading of SMD (Surface-Mount Device) carrier tapes is crucial to maintaining the integrity of electronic components. One of the primary strategies to minimize component damage is to ensure that the tapes are stored in a controlled environment. Temperature and humidity fluctuations can compromise the materials used in carrier tapes, leading to deterioration or warping. By keeping the tapes in a stable environment, you can significantly reduce the risk of damage during transport and handling.

Another essential tip is to utilize specialized loading tools designed for SMD components. These tools enhance precision when inserting components into the tape, thereby minimizing the likelihood of slips or misalignments that could cause scratches or breakage. Additionally, train your staff on the importance of gentle handling of the tapes, emphasizing that excessive force can easily damage both the tape and the components.

Lastly, it’s vital to perform regular inspections of both the carrier tapes and loaded components. This practice helps identify any potential issues early, allowing for timely adjustments before damage occurs. By implementing these strategies, businesses can ensure a higher success rate in maintaining component integrity while optimizing their SMD carrier tape usage.

| Strategy | Description | Benefits | Implementation Tips |

|---|---|---|---|

| Controlled Environment | Maintain appropriate humidity and temperature while handling and storing SMD tapes. | Reduces moisture exposure and static charge. | Use dehumidifiers and thermoregulators. |

| Proper Loading Techniques | Follow manufacturer guidelines for loading components onto the carrier tape. | Minimizes component damage and misalignment. | Train operators on correct methods and tools. |

| Use of ESD Protection | Implement electrostatic discharge (ESD) controls during handling. | Prevents damage to sensitive components. | Utilize ESD mats, wrist straps, and grounded equipment. |

| Regular Inspection | Conduct routine checks of carrier tapes for defects. | Identifies issues before they affect production. | Schedule inspections daily or weekly based on volume. |

| Training for Staff | Educate workers on best practices for handling SMDs. | Improves overall handling and reduces damage. | Provide workshops and training sessions regularly. |

| Correct Tape Size | Select the appropriate carrier tape width for the components. | Ensures secure fit and minimizes vibration during transport. | Refer to component specifications for tape size. |

| Avoiding Overloading | Do not exceed the recommended loading capacity of tapes. | Prevents mechanical stress on components. | Follow guidelines for maximum component quantity. |

| Use of Quality Tapes | Purchase high-quality carrier tapes to avoid defects. | Enhances reliability in the production process. | Source from reputable suppliers with quality certifications. |

| Minimize Handling | Reduce the number of times components are handled. | Lowers risk of damage through unnecessary movement. | Plan for streamlined processes to limit handling. |

| Documentation and Tracking | Keep detailed records of carrier tape usage and component types. | Aids in quality control and traceability. | Use inventory management software for tracking. |

In the pursuit of higher throughput in electronic manufacturing, the integration of carrier tape with pick and place equipment has become a vital consideration. Carrier tapes are designed to hold electronic components in place, ensuring they can be efficiently fed into assembly lines. By streamlining this interface, manufacturers can significantly enhance the speed and accuracy of component placement, reducing both cycle times and potential errors during assembly processes.

Effective automation starts with selecting the right type of carrier tape that aligns with the specifications of both the components and the pick and place machinery. Employing adjustable feeders can also accommodate a variety of tape formats, allowing for a more versatile and efficient operation. Additionally, integrating sensors and advanced controls can further optimize the overall system performance, enabling real-time monitoring of component availability and placement precision. This integration not only boosts throughput but also minimizes waste, making the entire assembly process more cost-effective and sustainable.

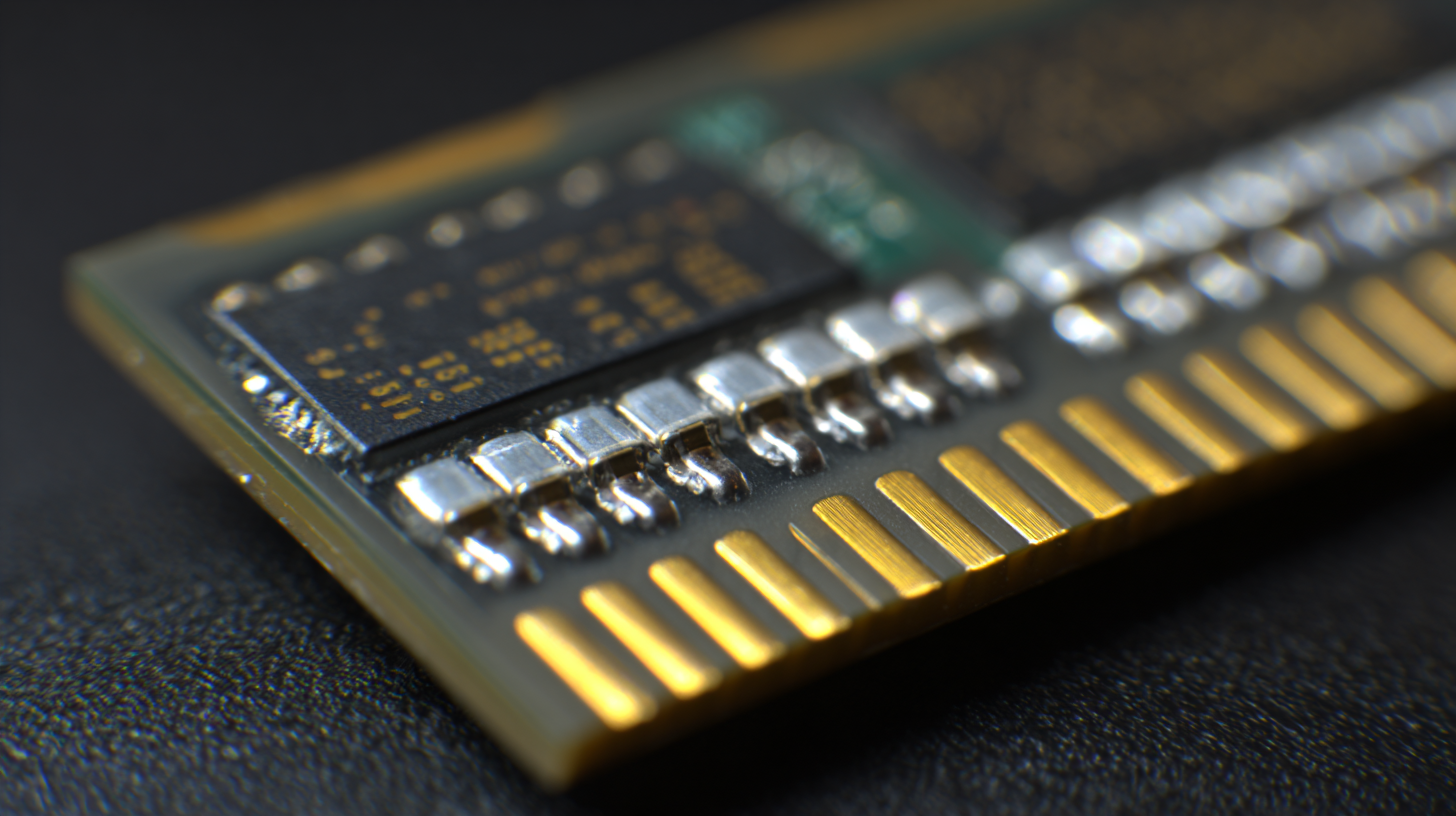

The performance and longevity of SMD electronic component carrier tape rely heavily on the quality of the materials used. In a recent study published by the Electronics Packaging Technology Journal, it was found that carrier tapes made from high-quality polyethylene offered significantly better moisture resistance than those made from lower-grade materials. This moisture resistance is critical, as encapsulated electronic components can suffer from delamination or corrosion when exposed to humidity, elevating the importance of selecting materials that meet stringent industry standards.

Adhesive performance also plays a crucial role in ensuring that components remain securely in place throughout the manufacturing process. According to the International Journal of Adhesion and Adhesives, carrier tapes with specially formulated adhesives provide enhanced retention strength and are less susceptible to temperature fluctuations. Notably, these advanced adhesives maintain their integrity in a variety of environmental conditions, which is essential for the reliability of the components during storage and transport. As manufacturers aim for higher efficiency and reduced production costs, incorporating carrier tapes with superior adhesive and material properties is imperative for long-term operational success.