Leave Your Message

As the demand for efficient packaging solutions continues to rise, the importance of selecting the right Plastic Carrier Tape becomes increasingly evident. According to a recent market analysis by Smith & Associates, the global plastic carrier tape market is projected to witness a robust growth rate of 7% annually, fueled by advancements in packaging technology and heightened consumer expectations for sustainability. In light of this burgeoning market, understanding the specific needs of your application is crucial to optimizing performance and cost-effectiveness.

Industry expert Dr. Emily Carter, a renowned packaging specialist, emphasizes the significance of informed decision-making in the selection process, stating, "Choosing the right Plastic Carrier Tape not only enhances product integrity but also contributes to overall operational efficiency." This sentiment reflects a broader trend within the industry where precision in material selection can lead to substantial improvements in production workflows.

As we navigate through the myriad of options available in the market, this guide aims to illuminate the key considerations for choosing the best Plastic Carrier Tape tailored to your specific requirements. By focusing on quality, compatibility, and environmental impact, businesses can align their packaging strategies with contemporary standards, ensuring optimal performance and customer satisfaction in an increasingly competitive landscape.

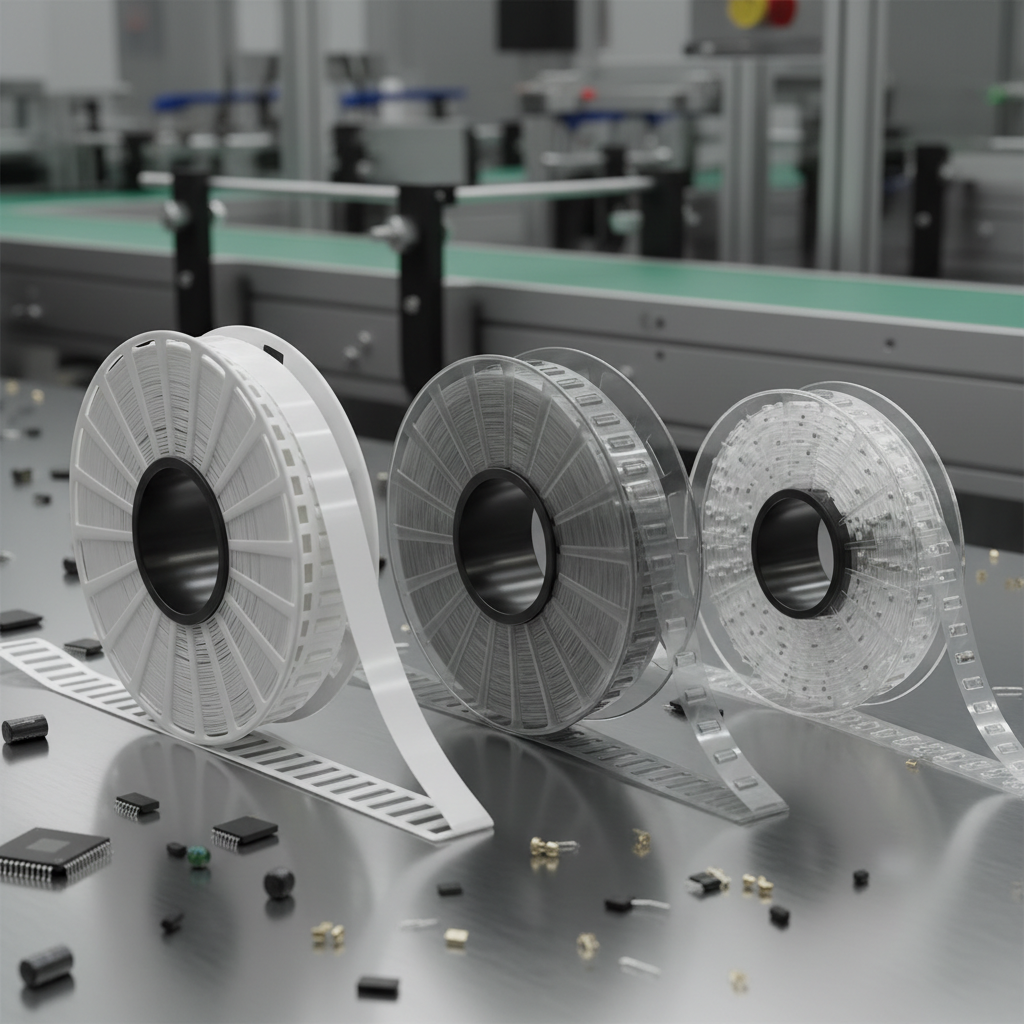

Plastic carrier tapes play a crucial role in the realm of automated manufacturing processes by providing an efficient means of handling and transporting electronic components. The primary advantage of using plastic carrier tapes lies in their ability to ensure precise alignment and protection of delicate components during the assembly line. This precision minimizes the risk of misplacement and damage, which are common issues in high-speed production environments. The consistent spacing and secure containment offered by these tapes enhance the overall flow of the manufacturing process, resulting in increased productivity and reduced downtime.

Moreover, plastic carrier tapes contribute to maintaining cleanroom standards essential in industries such as semiconductors and pharmaceuticals. Unlike traditional methods of component handling that might introduce contaminants, plastic carrier tapes are designed to minimize particulate generation, thereby preserving the integrity of sensitive components. Additionally, their lightweight yet durable structure allows for seamless integration with automated pick-and-place systems, promoting faster cycle times and improved operational efficiency.

As manufacturing technologies advance, the adoption of plastic carrier tapes not only streamlines production but also supports the sustainability goals of reducing waste and improving resource efficiency in automated processes.

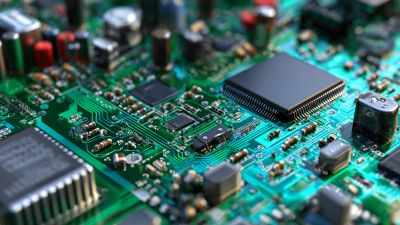

When selecting plastic carrier tape materials for your needs, several key factors must be considered to ensure optimal performance. First, assess the compatibility of the tape with the components it will carry. Different materials offer varying levels of adhesion and temperature resistance; for instance, polypropylene is often chosen for its durability, while polyester provides flexibility and transparency. Understanding the specific requirements of your application, including the types of components and environmental conditions, is crucial in making an informed decision.

Another significant factor is the tape’s surface texture and static dissipative properties. A smooth surface can facilitate easy placement of components, while a rough texture might help secure them better during transport. Additionally, if you are working with sensitive electronic components, opting for anti-static carrier tape may prevent damage from electrostatic discharge. Lastly, consider the cost-effectiveness of the materials in relation to their performance to ensure you are making a sound investment for your production line.

When selecting plastic carrier tape, understanding the impact of tape thickness is crucial for component protection and overall efficiency. Thicker tapes provide heightened rigidity, which can better safeguard delicate components during transportation and storage. This added stability minimizes the risk of damage due to external pressures, making it ideal for sensitive electronic parts. However, it's important to find a balance; overly thick tape may cause difficulties in feeding through automated placement machines, potentially affecting production speed.

Tips: Aim for a tape thickness that ensures adequate support for your components without compromising the operational efficiency of your machinery. Experiment with different thicknesses to find the sweet spot that maintains component integrity while allowing smooth handling.

Additionally, consider the materials used in the tape's construction. Some thicker tapes can lead to increased friction during feeding. Therefore, choosing a tape designed with smooth feeding characteristics can enhance efficiency during the manufacturing process. Regular assessments of your chosen tape's performance will help ensure that it continues to meet your production needs effectively.

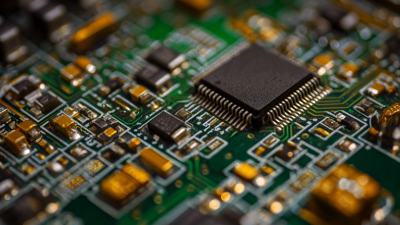

When selecting the best plastic carrier tape, understanding the different types of adhesives is crucial for optimal performance. Each adhesive type, whether it be acrylic, rubber, or silicone-based, has unique properties that affect adhesion strength and environmental resistance. Acrylic adhesives, for instance, offer excellent UV resistance and are ideal for outdoor applications, whereas rubber adhesives provide strong initial tack, making them suitable for quick applications on various surfaces. Additionally, silicone-based adhesives excel in high-temperature environments and are often used in specialized applications.

In the context of thermal interface materials, the choice of adhesive type can also significantly influence performance. For example, silicone adhesives are often preferred for thermal management due to their flexibility and ability to fill gaps, thus ensuring efficient heat transfer. On the other hand, epoxy adhesives provide superior bonding strength and durability, making them a go-to choice for applications that demand long-term reliability. As the market continues to evolve, understanding the properties of these adhesive types will aid in choosing the right plastic carrier tape tailored to specific needs, enhancing both product longevity and performance.

When selecting the best plastic carrier tape for your needs, understanding industry standards and certifications is crucial. Carrier tapes are essential for packaging electronic components, and the quality of these tapes can greatly affect the overall efficiency of your manufacturing process. Look for compliance with international standards such as EIA-481, which outlines the requirements for carrier tape dimensions and performance. This ensures that the tape will securely hold components in place, minimizing the risk of damage during transport and assembly.

Additionally, certifications such as ISO 9001 can serve as indicators of a manufacturer's commitment to quality management systems. This certification is particularly important as it reflects the ability to consistently provide products that meet customer and regulatory requirements. Furthermore, check for environmental certifications like RoHS or REACH, which ensure that the materials used in the carrier tapes do not contain harmful substances. By focusing on these standards and certifications, you can make informed decisions that will enhance your production efficiency and product reliability.