Leave Your Message

The advent of automation and smart manufacturing has necessitated the integration of advanced technologies that enhance operational efficiency and product quality. Among these innovations, "Touch-Sensitive Spring" technology has emerged as a pivotal component, facilitating more intuitive human-machine interactions. According to a recent report by the International Federation of Robotics, the global market for smart manufacturing is projected to reach $500 billion by 2025, indicating a significant shift towards more intelligent systems. Touch-Sensitive Springs are at the forefront of this transformation, providing real-time feedback and adaptability in intricate assembly processes.

This technology not only improves the precision of tasks but also enhances safety and user experience, addressing the growing demand for customized and versatile production methods. As industries seek to implement more connected and responsive systems, exploring the future of Touch-Sensitive Spring technology becomes paramount in refining manufacturing processes and maintaining competitive advantage.

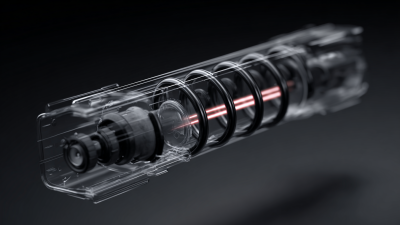

The advancements in touch sensitive spring technology are revolutionizing automation in smart manufacturing, providing enhanced feedback and control mechanisms that were previously unattainable. This technology integrates miniature sensors that can detect pressure and tactile feedback, enabling machines to respond intuitively to human interactions. Recent developments in high-performance MEMS pressure sensors illustrate this trend, as these sensors are essential in numerous sectors, including aerospace and automotive industries, where precision and reliability are paramount.

Research indicates that the market for MEMS sensors is projected to grow at a compound annual growth rate (CAGR) of 9.2% through 2025, driven by advancements in design and fabrication techniques. The integration of touch sensitive springs with these sensors not only improves efficiency in automation processes but also enhances user experience by providing real-time feedback. For instance, in assembly lines, the application of this technology allows for greater precision in tasks that require delicate handling, ultimately reducing error rates.

**Tips:** When considering the implementation of touch sensitive spring technology in your operations, ensure compatibility with existing systems and assess the potential ROI. Additionally, investing in training for your workforce will maximize the benefits of automation and enhance overall productivity. Stay informed on industry trends to adapt to emerging technologies that can further optimize your processes.

This chart illustrates the increasing market adoption rate of touch sensitive spring technology in smart manufacturing from 2019 to 2023. The advancements in this technology are enhancing automation, leading to greater efficiency and versatility in manufacturing processes.

The integration of touch-responsive mechanisms in smart manufacturing systems presents a transformative approach to enhancing operational efficiency and interaction within industrial environments.

Recent advancements in soft robotics, coupled with the development of active electronic skins, offer promising pathways for creating smart surfaces that can respond to human touch and environmental stimuli. This haptic feedback technology enables real-time communication between machines and workers, greatly improving workflow and productivity. Reports indicate that smart factories employing such technologies have reported efficiency gains of 15-25%, showcasing the impact of automation and sensor integration on manufacturing processes.

Tips: To optimize the implementation of touch-sensitive technologies, manufacturers should prioritize the seamless integration of collaborative robots with existing workflows. This can minimize disruptions while maximizing the benefits of enhanced sensing and actuation capabilities. Additionally, training staff to interact effectively with these technologies can significantly elevate operational success.

Moreover, the strategic adoption of integrated sensors within manufacturing rotational mechanisms exemplifies the potential of responsive systems.

These smart hinges not only provide real-time status updates but also interact effortlessly with other elements in the production line. As smart manufacturing continues to evolve, leveraging these touch-sensitive methodologies will be essential in building resilient and adaptive industrial ecosystems.

Digital transformation is reshaping industries across the board, and the spring technology sector is no exception. As smart manufacturing continues to evolve, the integration of advanced digital tools enables manufacturers to improve product design and production processes significantly. With technologies like AI and cloud computing, companies can enhance their responsiveness to market demands, optimize their supply chains, and foster innovation in spring design and applications.

Moreover, the emphasis on digital logistics platforms reflects a broader trend within manufacturing, improving efficiency and resilience in operations. By adopting these platforms, manufacturers can streamline transportation and logistics, ensuring that spring technology innovations reach the market more swiftly. As a result, digital transformation not only addresses the immediate challenges faced within the industry but also positions companies for future growth, pushing the boundaries of what touch-sensitive spring technology can achieve in smart manufacturing.

The integration of touch sensitive spring technology in smart manufacturing presents both exciting opportunities and significant challenges. One primary challenge is the varying degrees of sensitivity required for different applications. Manufacturers must ensure that these components can accurately detect touch across a range of conditions, including varying pressure levels and environmental factors. This inconsistency can lead to operational inefficiencies, as components may fail to respond appropriately under certain conditions.

To address these challenges, innovative solutions are necessary. One potential approach involves the development of advanced materials that can enhance the sensitivity of touch-sensitive springs while maintaining durability and responsiveness. Additionally, establishing rigorous testing protocols can help identify and rectify issues related to sensitivity, ensuring that components meet the required standards before implementation. Collaboration between engineers and manufacturers can also pave the way for creating tailored solutions that cater to specific industry demands, ultimately driving efficiency and productivity in smart manufacturing environments.

The future of smart manufacturing is being reshaped by touch technology, which is becoming increasingly pivotal in creating intuitive and efficient manufacturing environments. Recent industry reports indicate that the global electronic manufacturing services (EMS) market is projected to grow from $609.79 billion in 2024 to approximately $648.1 billion by 2025 and potentially reach $1 trillion by 2032. This growth underscores the demand for advanced technologies, including touch-sensitive interfaces that enhance human-machine interaction and operational efficiency.

Events like the upcoming Global Computing Conference (CGC2025) in Shenzhen reflect the industry's commitment to showcasing innovations in touch-sensitive technology. With an immersive exhibition area designed to display cutting-edge applications, CGC2025 will highlight how touch technology is not just enhancing equipment interfaces but also driving the entire smart manufacturing ecosystem forward. Furthermore, seminars across numerous trade shows will delve into trends such as AI integration and automated processes, which are expected to bolster the adoption of touch-sensitive technologies in various sectors, paving the way for a more connected and responsive manufacturing landscape.