Leave Your Message

Selecting the right carrier tape reel is a crucial aspect of ensuring the safe and efficient handling of electronic components in the manufacturing and assembly processes. Carrier tape reels play a vital role in the delivery of components to automated pick-and-place machines, providing a standardized method of organization that enhances workflow and minimizes the risk of damage. As the demand for precision and speed in electronic assembly grows, so does the importance of understanding the characteristics and specifications of carrier tape reels.

When choosing a carrier tape reel, it is essential to consider several factors, including the dimensions of the components, the reel size, and the type of material used in the tape. Each of these elements can significantly impact not only the reliability of component transport but also the overall efficiency of production lines. Moreover, with a wide variety of carrier tape reels available in the market, making an informed choice can help in achieving optimal compatibility with existing systems, ultimately leading to a smoother manufacturing process.

In this article, we will explore the key considerations to keep in mind when selecting a carrier tape reel, providing you with the insights needed to make the best decision for your electronic component needs. Understanding these factors will empower manufacturers and engineers to streamline their production processes while maintaining high-quality standards throughout their operations.

Choosing the right carrier tape dimensions for your electronic components is crucial for ensuring safe and efficient transportation. The dimensions of the carrier tape should closely match the size and shape of the components to prevent movement during shipping. Using a carrier tape that is too large can result in components becoming dislodged, while one that is too small might cause damage.

When determining the appropriate carrier tape for your components, consider these factors:

Tips: Always refer to the component datasheet for specific dimensions and tolerances. If you're dealing with new or custom components, performing a trial run with various tape sizes can help identify the best fit. Finally, ensure that the carrier tape material is compatible with the environment it will be used in, to avoid any potential damage to the components.

When selecting the appropriate carrier tape reel for electronic components, the choice of materials plays a pivotal role in ensuring optimal protection during transportation and storage. Carrier tapes are typically made from various polymers that offer distinct advantages; for instance, antistatic materials can prevent electrostatic discharge (ESD), which is crucial for sensitive components. Using materials with a suitable thickness and flexibility also helps to safeguard delicate parts from mechanical stress, ensuring that they are delivered in pristine condition to the assembly line.

Moreover, the compatibility of the carrier tape with the components it holds cannot be overlooked. Different components have varying sizes and shapes, necessitating a tailored approach to carrier tape design. Materials like polycarbonate and polyester are frequently used due to their durability and resilience. Choosing the right material not only enhances protection but also streamlines the handling process, reducing the risk of damaging components during manual or automated loading. Thus, understanding the importance of carrier tape materials is essential for maintaining the integrity of electronic components throughout their lifecycle.

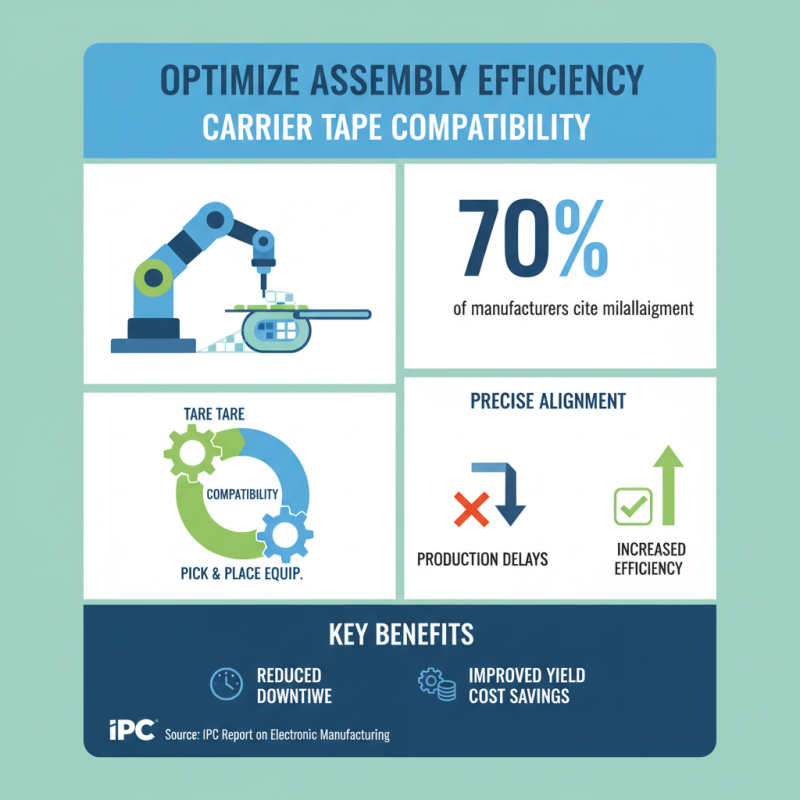

When selecting a carrier tape reel for electronic components, ensuring compatibility with pick-and-place equipment is crucial for optimizing assembly efficiency. According to a report by IPC, over 70% of electronic manufacturers cite misalignment during the pick-and-place process as a significant cause of production delays. This highlights the importance of aligning the carrier tape dimensions precisely with the specifications of the automated equipment in use.

Compatibility involves several factors, including the width and pitch of the carrier tape, as well as the specific component requirements. The EIA-481 standard provides guidelines on carrier tape dimensions, which help in selecting the right tape that matches the feeder specifications of pick-and-place machines. For instance, a study indicated that using incompatible carrier tape can lead to up to a 20% increase in component drop rates during assembly, translating to higher costs and longer downtimes. Therefore, investigating the specifications provided by the equipment manufacturer, alongside industry standards, is essential for achieving seamless integration and efficiency in the manufacturing process.

When choosing the right carrier tape reel for electronic components, it’s crucial to understand various industry standards and specifications. Carrier tapes are essential for the automated assembly of electronic components, ensuring reliable handling and transport throughout the manufacturing process. These tapes come in different sizes and materials, each designed to accommodate specific component shapes and weights. It's vital to review the requirements such as the dimensions of the components and the reel specifications to ensure compatibility.

Tips: Always verify the compatibility of the carrier tape with the component sizes. Refer to standard specifications such as EIA-481 for guidance on reel dimensions. Additionally, consider the material of the tape; choosing between polycarbonate, polyvinyl chloride, or other materials depends on the environmental factors and handling processes the components will encounter.

Another essential factor is the perforation pitch of the carrier tape. This determines how well the tape aligns with automation equipment. Ensuring the correct pitch can significantly enhance efficiency during assembly. It's advisable to consult with the manufacturer's guidelines or industry standards to select the right pitch that matches your assembly line's requirements.

| Dimension | Standard Value | Importance | Notes |

|---|---|---|---|

| Reel Diameter | 7 inch, 13 inch, 15 inch | Critical for storage and handling | Choose based on machine compatibility |

| Carrier Tape Width | 8mm, 12mm, 16mm, 24mm | Affects pick and place accuracy | Select based on component size |

| Pocket Depth | 3.0mm, 5.0mm | Ensures component stability | Adjust based on component height |

| Pocket Width | 1.0mm to 15.0mm | Needed for compatibility | Match to component specifications |

| Distance Between Pockets | 3.5mm, 5.5mm | Crucial for spacing and reliability | Follow industry standards |

When it comes to storing and handling carrier tape reels for electronic components, following best practices is crucial to maintain the integrity and functionality of the components. One fundamental step is to store the reels in a controlled environment, ideally with stable temperature and humidity levels. Excessive moisture can lead to corrosion and impact the performance of sensitive electronic parts, while extreme temperatures can cause distortion in the tape material. Utilizing anti-static bags or bins is also advisable to protect the components from static electricity, which can cause irreversible damage.

Another important aspect of handling carrier tape reels is to ensure proper organization and labeling. Clearly marking each reel with details such as part number, date received, and storage location not only aids in easy retrieval but also minimizes the risk of mix-ups. Additionally, when dispensing components from the tape, use appropriate tools to avoid damaging the tape or the parts themselves. Gentle handling, along with maintaining a clean workspace, can significantly reduce the risk of contamination or physical damage to the electronic components. By adhering to these best practices, you can extend the lifespan of your carrier tape reels and ensure the reliability of your electronic assemblies.