Leave Your Message

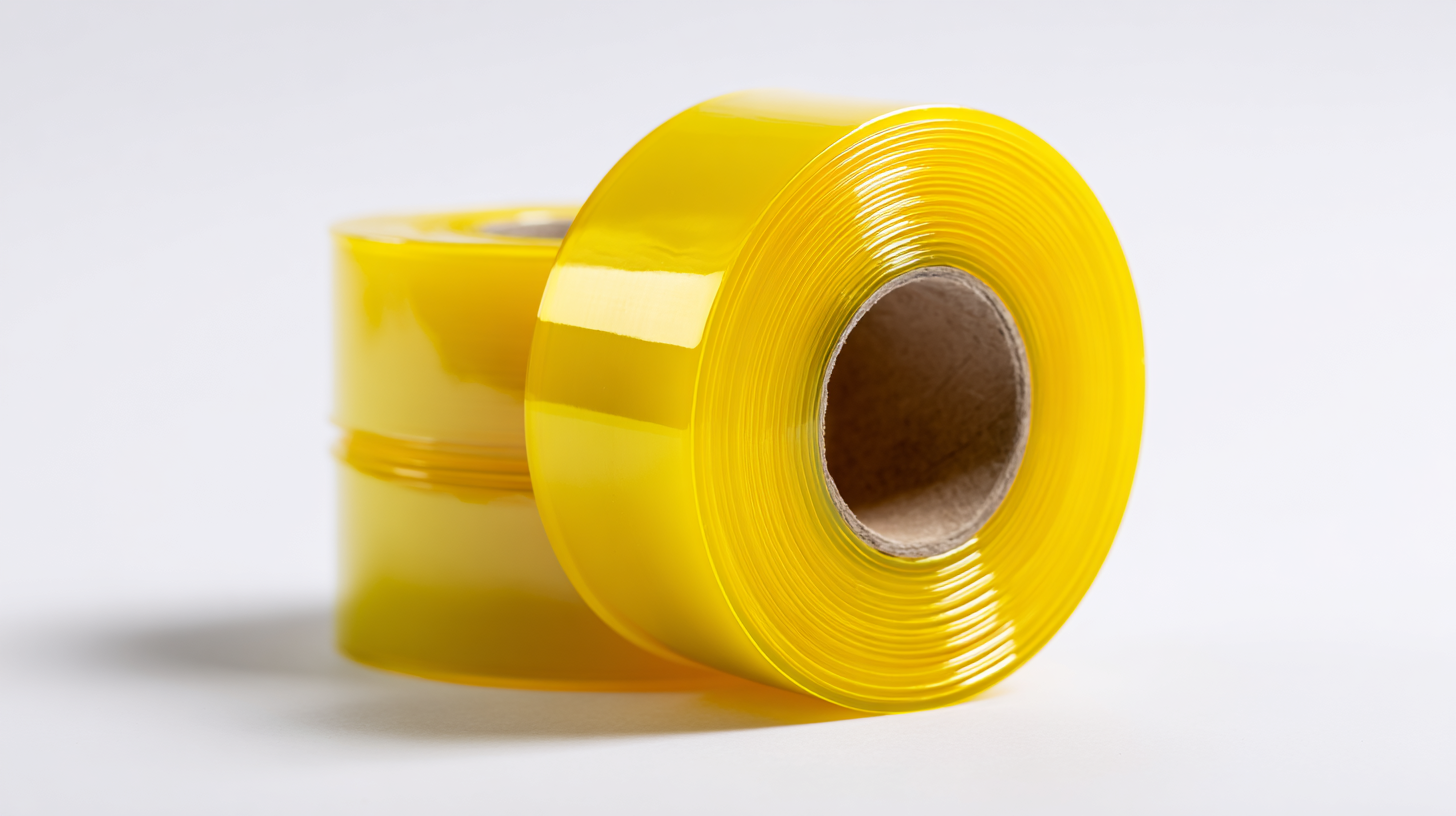

In the fast-paced world of manufacturing and packaging, efficiency and reliability are paramount. Plastic Carrier Tape has emerged as a vital component in optimizing the packaging process, aiding in the protection and transport of goods while significantly reducing production time. According to a report by Smithers Pira, the global flexible packaging market is expected to reach $300 billion by 2024, with innovations in materials such as Plastic Carrier Tapes playing a crucial role in this growth. These tapes not only streamline operations but also enhance product presentation and reduce waste, aligning with sustainable manufacturing practices. As industries increasingly seek ways to improve packaging efficiency, the selection of the right Plastic Carrier Tape becomes essential for maintaining competitiveness and ensuring customer satisfaction.

When selecting plastic carrier tapes for packaging, several critical factors should be taken into consideration to enhance operational efficiency. Firstly, the thickness and material of the carrier tape play a significant role in its durability and performance. A thicker tape may offer better support for components, especially in automated processes, but it is essential to balance strength with flexibility to avoid damage during application. Additionally, the type of adhesive used can affect both the ease of use and the integrity of the bond, making it crucial to choose a tape that adheres well to the intended surfaces without leaving residue.

Another important aspect to evaluate is the compatibility of the carrier tape with the specific packaging equipment being used. Different machines may require different tape configurations, such as perforation or width. It’s advisable to consult equipment specifications to ensure that the selected tape functions seamlessly with your machinery. Furthermore, the environmental conditions of the storage and shipping environments should also influence your choice; tapes that can withstand extreme temperatures or humidity will be vital for maintaining package integrity. By carefully assessing these factors, businesses can select the best plastic carrier tapes to meet their unique packaging needs efficiently.

When it comes to optimizing packaging processes, choosing the right plastic carrier tape is crucial. In various packaging scenarios, different types of carrier tapes can enhance efficiency significantly. For high-speed packaging lines, tapes with strong adhesion and quick release properties are essential, ensuring that products stay securely in place during transit. For instance, clear, durable polyethylene tapes often excel in environments where visibility and strength are critical, making them ideal for retail packaging.

Moreover, specialized carrier tapes that offer moisture resistance can be invaluable for industries dealing with perishable goods. These tapes not only protect the integrity of the packaging but also ensure that the contents remain fresh and uncontaminated during shipping. Additionally, printed carrier tapes can serve a dual purpose by providing branding benefits while maintaining the integrity of the package. Adopting the right type of plastic carrier tape tailored to specific packaging requirements leads to enhanced productivity and minimizes waste, ultimately contributing to a smoother operation.

High-quality plastic carrier tapes offer a range of benefits that significantly enhance packaging efficiency. Designed to ensure secure transportation and storage, these tapes provide superior adhesion and durability compared to conventional packaging materials. With their ability to withstand various environmental conditions, they maintain their integrity during transit, thereby reducing the likelihood of product damage and enhancing overall reliability.

Additionally, plastic carrier tapes are often lightweight and flexible, which aids in reducing shipping costs while optimizing space within packaging. Their easy-to-use features help streamline the packing process, allowing for quick application and minimizing labor time. By utilizing these advanced tapes, businesses can improve their packaging speed without sacrificing quality, ultimately leading to increased customer satisfaction and loyalty. The investment in high-quality plastic carrier tapes can result in long-term savings and efficiency gains, making them an essential component of modern packaging strategies.

When it comes to applying plastic carrier tapes, proper technique is essential to achieving optimal results. First, ensure that the surface you are working on is clean and dry, as any dust or moisture can interfere with adhesion. Lay the tape flat and press down firmly to eliminate air bubbles, which could weaken the bond. It’s important to use the right amount of tension while applying the tape; too much can cause it to stretch or tear, while too little might result in inadequate adhesion.

Additionally, consider the temperature and humidity conditions in which you are applying the tape. Extreme temperatures can affect the tape’s performance, so it’s best to apply it in a controlled environment. After application, allow sufficient time for the adhesive to cure before subjecting the taped area to stress or load. By following these guidelines, you can enhance your packaging efficiency and ensure that your product is securely wrapped.

| Tape Type | Material | Width (mm) | Thickness (mm) | Adhesive Type | Temperature Resistance (°C) |

|---|---|---|---|---|---|

| Standard Plastic Carrier Tape | Polypropylene | 12 | 0.15 | Acrylic | 80 |

| High-Temperature Tape | Polyimide | 10 | 0.05 | Silicone | 260 |

| Conductive Carrier Tape | ESD Polypropylene | 15 | 0.2 | Acrylic | 90 |

| Heavy-Duty Carrier Tape | Polyethylene | 20 | 0.3 | Rubber | 70 |

| UV Resistant Tape | Polyester | 25 | 0.1 | Acrylic | 85 |

| Low-Temperature Carrier Tape | Polypropylene | 12 | 0.15 | Rubber | -20 |

| Biodegradable Tape | PLA | 15 | 0.1 | Acrylic | 60 |

Plastic carrier tapes have become a game-changer in the packaging industry, providing innovative solutions that enhance efficiency and streamline processes. These tapes are designed to hold, protect, and transport a variety of products securely. Their flexibility allows them to be customized for different shapes and sizes, making them ideal for packaging electronics, medical devices, and even consumer goods. The precise application of adhesive technology ensures that products remain intact during shipping and handling, minimizing damage and returns.

Plastic carrier tapes have become a game-changer in the packaging industry, providing innovative solutions that enhance efficiency and streamline processes. These tapes are designed to hold, protect, and transport a variety of products securely. Their flexibility allows them to be customized for different shapes and sizes, making them ideal for packaging electronics, medical devices, and even consumer goods. The precise application of adhesive technology ensures that products remain intact during shipping and handling, minimizing damage and returns.

Tips for effective use of plastic carrier tapes include ensuring the surface is clean and dry before application to achieve maximal adhesion. Consider using double-sided tapes for heavier items to distribute weight evenly and reduce strain on the packaging. Additionally, always test the tape on different materials to ensure compatibility, especially when working with sensitive items.

Furthermore, incorporating features like easy-peel or perforated designs can significantly enhance the user experience. When selecting a carrier tape, opt for those with high durability and resistance to various environmental factors. This not only prolongs the life of the packaging but also reflects positively on your brand's commitment to quality. Exploring these innovative uses will truly elevate your packaging solutions.