Leave Your Message

As we move towards 2025, the packaging industry is undergoing significant transformations, particularly in the realm of Tape Reel Packaging. This innovation is crucial for enhancing the efficiency of supply chains, and according to a report by Smithers Pira, the global flexible packaging market, which includes Tape Reel Packaging, is projected to reach $307 billion by 2026. This surge highlights the increasing demand for sustainable and efficient packaging solutions, where Tape Reel Packaging stands out due to its ability to streamline the assembly process and reduce waste.

The importance of Tape Reel Packaging cannot be overstated, especially in sectors such as electronics and automotive, where precise components are essential. A recent study by Freedonia Group indicates that efficient packaging methods can improve logistics performance by up to 30%. With advancements in materials and technologies, the next wave of innovations in Tape Reel Packaging will likely focus on not only enhancing durability and protection of components but also integrating smart tracking features that optimize inventory management. As we anticipate the top 10 innovations set to revolutionize Tape Reel Packaging in 2025, it is clear that these developments will play a pivotal role in driving supply chain efficiency and meeting the demands of a rapidly evolving market.

The demand for sustainable practices in packaging has led to the exploration of eco-friendly materials for tape reel packaging. Revolutionary innovations are being introduced to replace conventional plastics with biodegradable and recyclable alternatives. Materials such as plant-based bioplastics and recycled paper not only reduce waste but also minimize the carbon footprint associated with production and disposal processes. These options ensure that packaging remains functional while being gentler on the environment.

Furthermore, advancements in adhesive technologies are enhancing the efficiency of tape reel packaging. These new adhesives are designed to be strong yet eco-conscious, allowing for reliable sealing without compromising sustainability. Innovations like water-based adhesives and solvent-free alternatives are gaining traction, contributing to safer and more environmentally responsible supply chains. By prioritizing eco-friendly materials in tape reel packaging, companies can achieve efficiency and sustainability, proving that innovation in packaging can align with environmental stewardship.

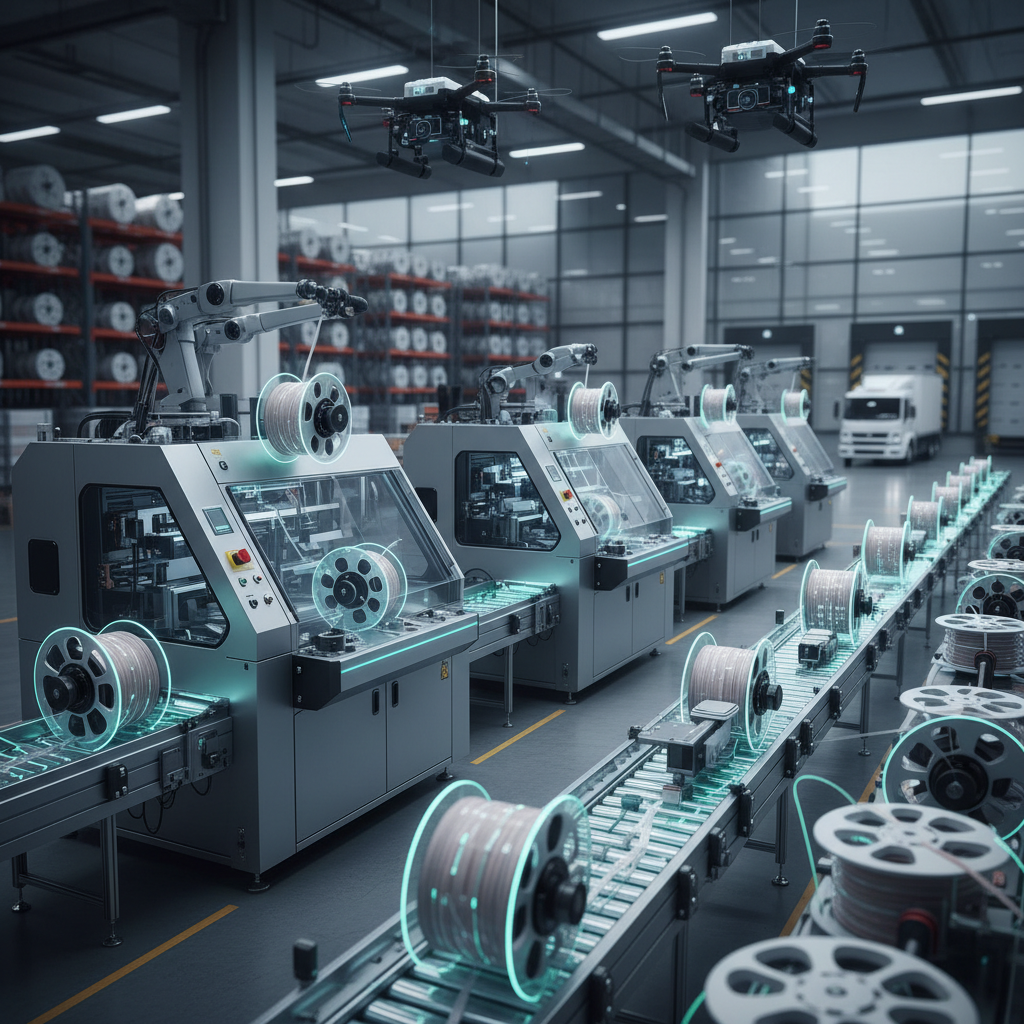

The rise of smart sensors is revolutionizing the way tape reel packaging is managed within supply chains. These innovative devices are embedded within the packaging to provide real-time tracking and monitoring, enhancing operational efficiency and reducing the likelihood of errors. By collecting data on temperature, humidity, and location, smart sensors ensure that products are stored and transported under optimal conditions. This capability not only safeguards product integrity but also minimizes waste, proving essential in industries where precision is paramount.

Moreover, the integration of smart sensors facilitates a smoother flow of information across the supply chain. As data is transmitted instantly to manufacturers and distributors, they can respond quickly to any disruptions, such as delays or equipment malfunctions. The predictive analytics powered by this data allows for better inventory management and demand forecasting, ultimately leading to cost savings. With smart sensors in tape reel packaging, companies can achieve greater transparency and adaptability, positioning themselves to meet the dynamic challenges of modern supply chains effectively.

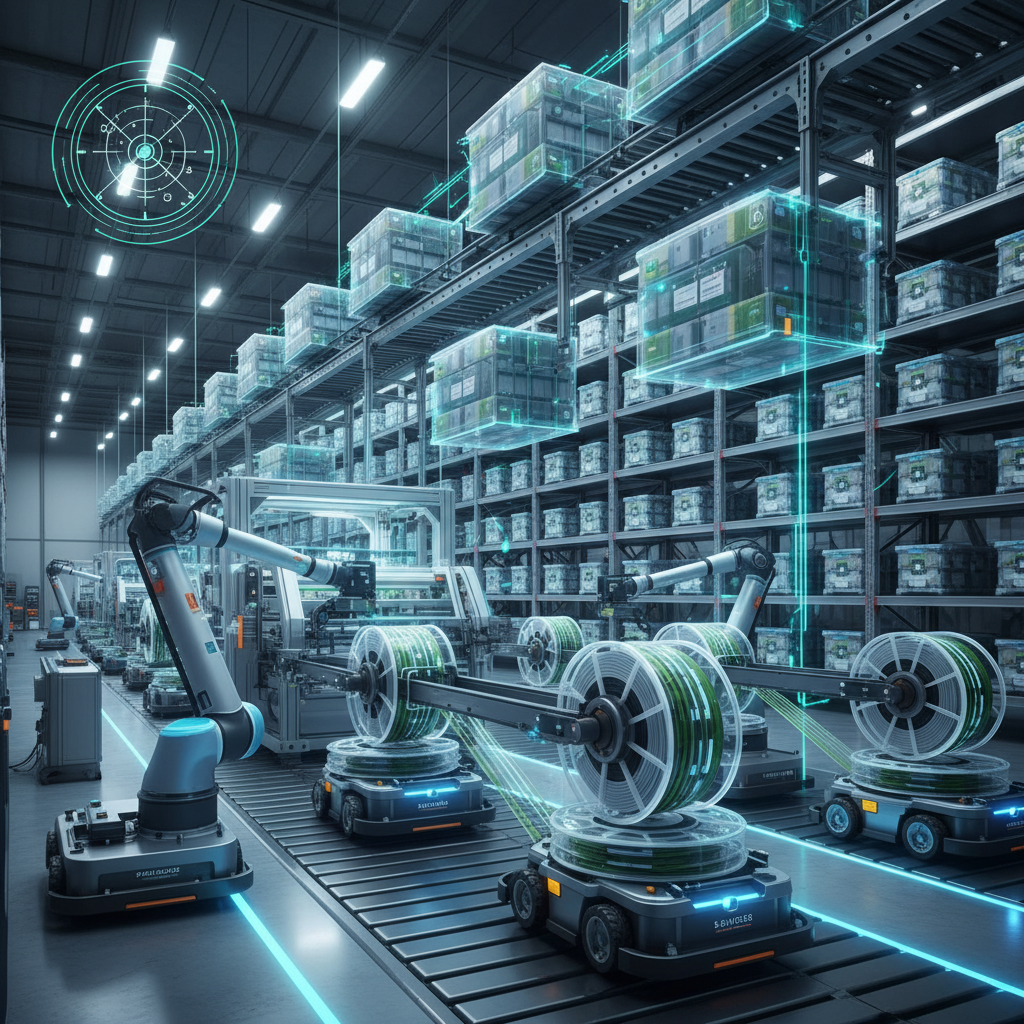

The future of tape reel packaging is increasingly focused on automation to enhance efficiency in production and distribution. Automated systems are revolutionizing how businesses manage their supply chains, cutting down on human error, and significantly increasing throughput. By incorporating robotic arms and intelligent conveyor systems, companies can achieve faster packing speeds and minimize labor costs. This shift towards automation not only streamlines processes but also ensures consistency and precision in packaging, which is essential for maintaining product integrity throughout the supply chain.

**Tip:** When considering an automated solution, assess the compatibility of your current systems. Integrating new technologies with existing infrastructure can maximize efficiency and reduce implementation costs.

Furthermore, the data analytics capabilities of automated systems provide insights that can help optimize inventory management. Businesses can track performance in real-time, enabling them to predict demand and manage stock levels effectively. This proactive approach reduces waste and ensures that production aligns with market needs.

**Tip:** Implement a scalable automated system that can adapt to future demands. This flexibility will allow your packaging operations to grow alongside your business without requiring complete overhauls.

Customizable designs in tape reel packaging are rapidly transforming the landscape of supply chains, offering tailored solutions that cater to diverse needs of manufacturers and end-users. According to a recent report by the Packaging Innovation Institute, over 70% of companies in the electronics and automotive sectors are now seeking packaging that can be easily adapted to fit various product specifications. This trend is driven by the increasing demand for flexibility in production processes, where companies require packaging solutions that not only protect their products but also streamline logistics.

The ability to customize tape reel packaging extends beyond mere size adjustments. Innovations such as adjustable reel dimensions, integrated labeling systems, and environmentally-friendly materials offer manufacturers the means to optimize their packaging strategies. A study from the Global Packaging Research Group indicates that customizable packaging can reduce material waste by up to 30%, which is a significant step towards more sustainable practices. As businesses strive to enhance efficiency and minimize costs, the emphasis on personalized packaging solutions is set to shape future supply chain dynamics, making it imperative for companies to invest in these innovations to stay competitive.

In the rapidly evolving landscape of supply chain management, corporations worldwide are increasingly adopting artificial intelligence (AI) to enhance their operations and overcome challenges. According to a recent report by McKinsey, companies that deploy AI in their supply chain processes can achieve up to a 15% reduction in logistics costs while improving delivery times by nearly 20%. These improvements stem from AI's ability to analyze vast amounts of data, identify inefficiencies, and optimize routing and inventory management strategies.

As organizations strive to enhance their logistics maturity, one effective approach is to implement data-driven strategies that leverage AI capabilities. Four key strategies include adopting predictive analytics for demand forecasting, employing machine learning algorithms for inventory optimization, utilizing automation in warehousing and distribution processes, and enhancing supplier collaboration through real-time data sharing. Research by Gartner highlights that firms utilizing these strategies can achieve increased responsiveness to market changes, ultimately leading to heightened customer satisfaction and loyalty. Embracing AI not only streamlines operations but also positions businesses to adapt quickly to evolving consumer demands in a competitive marketplace.