Leave Your Message

In 2025, the packaging industry is anticipated to witness significant shifts driven by advancements in technology and changing consumer demands. According to a recent market report by Smithers Pira, the global market for automated packaging equipment, which includes Automatic Tape Machines, is projected to grow at a CAGR of 4.2% over the next five years, reaching approximately $5.5 billion by 2025. This growth underscores the increasing need for efficient, reliable, and cost-effective packaging solutions in a fast-paced market.

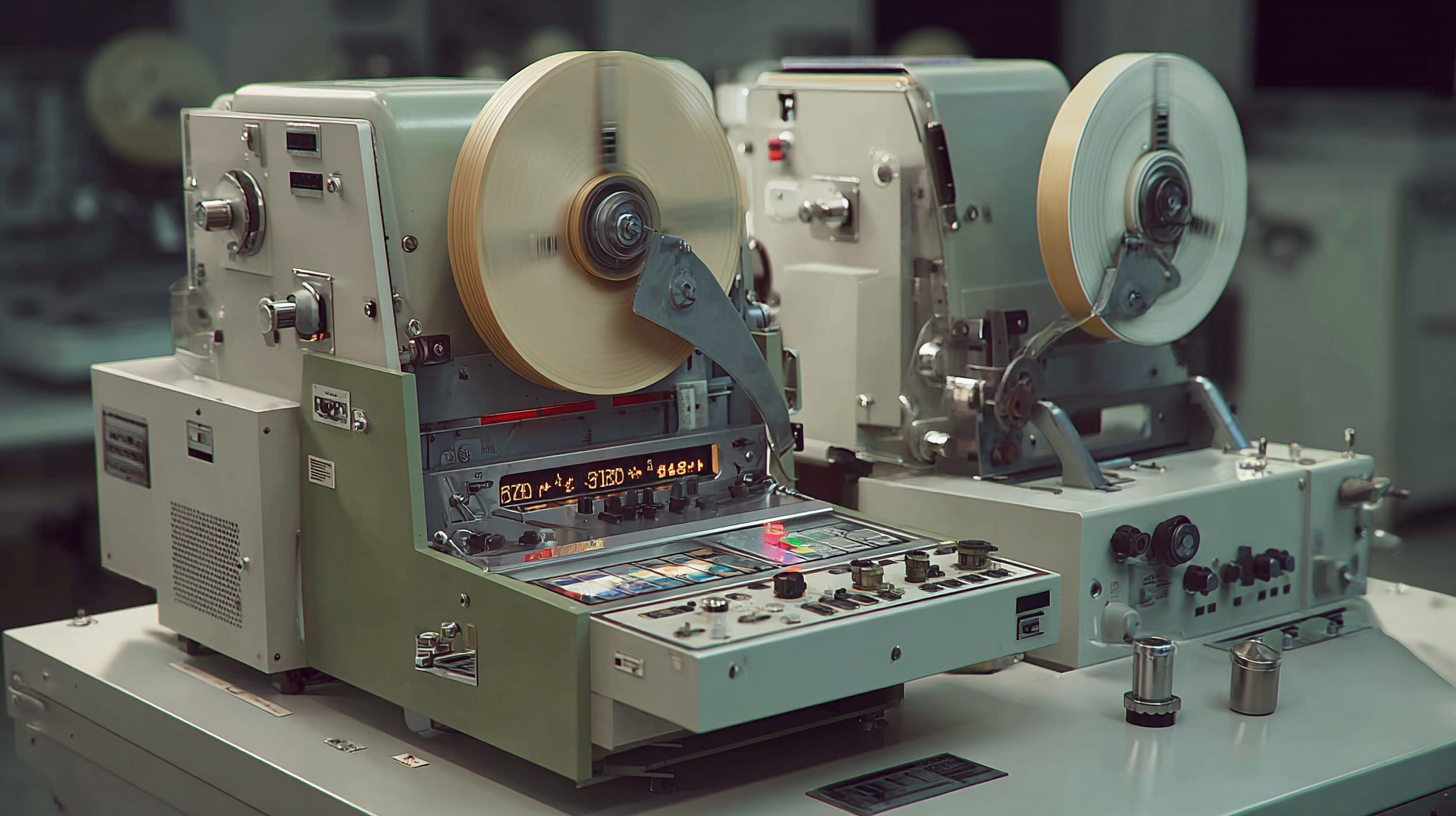

Automatic Tape Machines are at the forefront of this transformation, offering businesses enhanced operational efficiency, reduced labor costs, and improved product safety. By integrating these machines into their packaging lines, companies can not only streamline their processes but also meet the rising expectations for sustainable and high-quality packaging. As we explore the trends shaping the industry and the role of Automatic Tape Machines, it becomes clear that embracing automation is no longer just a competitive edge; it's a necessity for future success.

As we approach 2025, several emerging trends are reshaping industries worldwide, leading to innovative advancements that can significantly impact operational efficiency. One of the most notable trends is the growing emphasis on automation and smart technology. As businesses strive to enhance productivity, automatic tape machines are becoming pivotal. These machines not only minimize manual labor but also ensure precision in packaging processes, reducing errors and waste. This shift toward automation illustrates the broader industry movement towards integrating cutting-edge technology in daily operations.

Another critical trend is sustainability. As environmental concerns rise, companies are increasingly focusing on eco-friendly practices. Automatic tape machines that utilize recyclable materials or energy-efficient operations contribute to overall sustainability goals. By reducing their carbon footprint, businesses not only meet regulatory standards but also appeal to environmentally-conscious consumers. The integration of these machines can streamline packaging lines and support a circular economy, ultimately transforming how products reach the market while prioritizing ecological responsibility.

| Trend | Implications | Automatic Tape Machine Benefits | Industry Application |

|---|---|---|---|

| Sustainability | Increased focus on eco-friendly materials and practices | Reduced waste through precise tape usage | Packaging, Manufacturing |

| Automation | Labor shortages leading to increased automation investments | Increased efficiency and speed | Logistics, Warehousing |

| E-Commerce Growth | Expansion of online shopping driving packaging demand | Customizable and efficient packaging solutions | E-Commerce, Retail |

| Smart Technology | Integration of IoT in production processes | Remote monitoring and control capabilities | Manufacturing, Supply Chain |

| Personalization | Shift towards customized products | Versatile tape application for unique needs | Consumer Goods, Packaging |

In the rapidly evolving landscape of manufacturing, automatic tape machines are proving to be vital. Recent advancements, such as in-line variable spreading of carbon fiber and thermoplastic pre-preg tapes, enhance production efficiency in composite aerostructures. A study on in-process defect monitoring for automated tape laying highlights that the demand for high-performance composite manufacturing continues to grow, making automated tape placement not just beneficial, but essential.

The integration of automated systems influences not only productivity but also customization capabilities. As noted in the recent reports, the automated labeling machines market is projected to experience a compound annual growth rate (CAGR) of 4.3% from 2025 to 2034, reflecting the increasing reliance on automation in various sectors. For instance, innovative solutions like in-situ infrared annealing with automated fiber placement significantly reduce porosity while maintaining laydown efficiency. As industry players aim for greater sustainability and adaptability, the role of automatic tape machines becomes ever more consequential, redefining efficiency standards across manufacturing processes.

The bar chart above illustrates the projected increase in manufacturing efficiency through the adoption of automatic tape machines from 2021 to 2025. As companies integrate more advanced automation technologies, we expect to see a significant boost in their operational efficiency, culminating in an impressive 90% efficiency by 2025.

In the ever-evolving landscape of manufacturing, Chinese production capabilities stand out due to their blend of quality, cost-effectiveness, and vast global reach. Businesses looking to enhance their supply chains find that partnering with Chinese manufacturers not only reduces operational costs but also ensures consistent quality that meets international standards. With advanced production technologies and strict quality control processes, Chinese manufacturers are better equipped to deliver high-quality products that can stand the test of rigorous market demands.

Moreover, the competitive cost advantage provided by Chinese manufacturing is pivotal for businesses aiming to maintain the price advantage in their respective markets. By leveraging China's established infrastructure and skilled labor force, companies can significantly lower their production expenses without compromising on quality. This cost efficiency empowers businesses to reinvest savings into further innovation and expansion, positioning themselves favorably against competitors. As global trade networks become increasingly interconnected, the ability of Chinese manufacturers to reach various markets worldwide also expands the horizons for businesses looking to scale their operations internationally, facilitating easier entry into emerging markets while meeting diverse consumer demands.

In today's fast-paced industrial landscape, the integration of advanced tape application technology is revolutionizing business operations. Automatic tape machines are no longer just an auxiliary tool; they have become essential for optimizing efficiency and reducing waste. By automating the tape application process, businesses can ensure consistent quality and precision, significantly improving production workflows. This level of automation allows for faster turnaround times, enabling companies to respond promptly to market demands.

Moreover, advanced tape technology is enhancing versatility in packaging and assembling products. Companies can easily switch between different tape types and application settings, accommodating a wide range of materials and sizes without extensive downtime. This flexibility not only streamlines operations but also opens up new opportunities for innovation in product design and functionality. As businesses adopt these advanced solutions, they position themselves to meet customer needs more effectively while also minimizing operational costs in the long run. Embracing this technology is not just a trend; it is a strategic move toward future-proofing business operations.

In the rapidly evolving landscape of industry, investing in automation solutions is no longer just an option; it's a necessity for businesses looking to remain competitive. One of the key trends for 2025 is the shift towards automated processes, particularly in manufacturing and packaging.

Automatic tape machines exemplify this trend, providing unparalleled efficiency and precision in operations. By reducing manual labor, minimizing errors, and accelerating production speed, these machines enable companies to focus their resources on innovation and growth.

Automatic tape machines exemplify this trend, providing unparalleled efficiency and precision in operations. By reducing manual labor, minimizing errors, and accelerating production speed, these machines enable companies to focus their resources on innovation and growth.

Embracing automation not only streamlines workflows but also prepares businesses for future challenges. As customer demands become more complex and market dynamics shift unpredictably, companies equipped with advanced automation technologies will have the agility to adapt swiftly. Investing in such solutions positions businesses to meet rising expectations while maintaining cost-effectiveness.

As we move into an era where efficiency and responsiveness are paramount, automatic tape machines offer a powerful leverage point for any forward-thinking company aiming to thrive in the industry of the future.